The L'Aqua Paola, a fountain near our apartment in Rome.

After taking a hiatus from writing this blog for a while, I’ve decided that I will continue this blog from here in the States. From here on out, I’ll write something reasonably regularly. I certainly have more findings and “lessons learned” from my Rome project than I was able to include in the blog to date, plus I’ll bring in some findings and observations from my work here in the States.

I’ll also use the blog to post notice of various articles and lectures that come out of my Rome project. The first of these will be a lecture at the Boston Society of Architects Historic Resources Committee, on Thursday 14 October 2010, from 8:00 – 9:00 AM, at The Architects Building (5th floor conference Room), 52 Broad Street Boston MA. It’s free and open to the public, so please know that you are welcomed to attend if you happen to be in the Boston area that day. The slide lecture will summarize many findings from my Rome Project (as many of them as I can fit into an hour).

My final week in Rome was bittersweet – I’d grown so very fond of life in Rome over the past nine months, and I enjoyed my project so immensely that it was very difficult to leave. On one hand, I felt a sense of closure with my Fellowship, after my lecture, open studio and induction (“pinning ceremony” ) as a Fellow of the American Academy, and I was pleased with what I accomplished in my project. On the other hand, it was a time of sad goodbyes, both to the people we’d come to know and be friends with, and to the city we’d come to love.

- View across Rome from the L’Aqua Paola, near our apartment

Although we were frantically busy packing-up our apartment and my studio after 9 months, my wife Erin and I felt it was important that on our last day in Rome, we should stop packing for a few hours, and go for one final long walk through the city, past some of our favorite places, to see the city one last time, and to say goodbye to some of our shopkeeper friends at our favorite little shops (forno, pasticceria, farmacia, gelateria). Our ad-hoc route was meandering, and I kept suggesting we veer off a few blocks this way or a few blocks that way to walk by one building or another that I had studied as part of my project. After a while, my wife said to me “You’re saying goodbye to your buildings, aren’t you?” I hadn’t even realized it until she said it, but it dawned on me that she was right (as usual).

Bronski on Borromini's Oratorio dei Filippini

Caroline's first "Festa di compleanno" (birthday party) in the Bass Garden at the American Academy

Other expatriates who have lived in Rome tell me that it has a way of getting under your skin, inside your head, inside your heart, and it will always draw you back (that is, if you manage to leave at all). I’m sure it will draw us back many times. My daughter, who celebrated her first birthday just a few days before we left, will certainly appreciate Rome more when she is older.

Audrey Hepburn in Roman Holiday

I’m reminded of the scene at the end of the classic (and very much beloved in Rome) film Roman Holiday. At a press conference after a tour of many cities, a reporter asks Princess Ann (Audrey Hepburn) which city she enjoyed the most. She begins to give her practiced, perfectly diplomatic answer, saying how each city was unforgettable in its own way, and then she stops abruptly in mid-sentence, abandoning her well-rehearsed answer to interject “Rome. By all means Rome.”

We flew back to the U.S. on June 15. The first couple days back in the U.S. felt a little strange – it was strange to hear and see everything in English – radio, overheard conversations, signs, etc. It was strange to be able to communicate so effortlessly, and to understand absolutely everything everyone said. I hadn’t driven a car in over 9 months, so that felt a little strange too. I bought something and the change was going to be $3.14, so out of habit, I put my billfold away before the cashier gave me my change (the smallest paper currency in the EU is a 5, so in Italy 3.14 in change would be all coins.) Back in our house, where we’ve lived for about 10 years, it was strange that things didn’t seem more strange – it felt we’d been gone 2 weeks, not 9-1/2 months. The house only seemed different to my daughter, who was fascinated with our stairs, and took delight in promptly climbing them (crawling style) – our apartment in Rome was a flat, so interior stair climbing was a novelty to her.

I resumed work at Simpson Gumpertz & Heger (SGH) at the end of June. I’m really thankful for the support and encouragement that SGH provided to enable me to undertake this Fellowship, and also for allowing me to take the time off from work and still have my job when I returned. I’m also incredibly thankful to the National Endowment for the Arts, who funded my fellowship, and to the American Academy in Rome, who selected me for it, and supported, assisted, and encouraged me in all I was doing.

On the scaffold of San Andrea della Valle with Prof. Luciana Festa and conservator Emiliano

Rome:

- Roberta Rosati

- Antonietta Russo

- Simona Salvo

- Luciana Festa

- Luigi Prisco

- Giovanni Belardi

- Fabio Porzio

- Matteo & Biagio Ruperto

- Federica Giacomini

- Didier Repellin

- Angela Stahl

- Werner Schmid

- Domenico Minchilli

- Nicholas Stanley-Price

- Joe King

- Filippo Spaini

- Massimo DeCarolis

- Daniela Catanoso

- Dan O’Neill

- Maria Elisa Tittoni

- Alberta Campitelli

Milano, Brescia, Lodi, Aosta:

- Carlotta Coccoli

- Silvana Garufi

- Paola Villa

- Sergio Rettura

- Lorenzo Appolonia

Vicenza:

- Sonia Cattazzo

- Andreas Donadello

- Carlotta Coccoli

Ercolano Scavi (Herculaneaum excavations):

- Sarah Court

- Jane Thompson

- Paola Pressarezzi

American Academy in Rome:

- Chiara Bernazzani

- Eileen Ryan

- Darian Totten

- Aurelia D’Antonio

- Kiel Moe

- Scott Craver

- Giulia Barra

- Gianni Ponti

- Corey Brennan

- Et al

Grazie mille a tutti ( A thousand thanks to all)

Torte di Compleanno (birthday cakes)

Weeks 35-38 – The Calm after the Storm

Andrea Palladio's San Giorgio Maggiore, Venezia (Venice)

It might have seemed like I’d fallen into the lagoon, since I hadn’t posted a weekly blog entry in four weeks – my apologies. The past few weeks have been a whirlwind of activity and travel – additionally, virus problems reoccured on my computer, rendering it useless. We’ve just concluded the busiest time of year at the American Academy, and I’m now breathing sigh of relief after a frantic last few weeks.

Four weeks ago was my public lecture (or “shoptalk” as we call them) at the American Academy. With my computer incapacitated by another virus, I had to borrow a computer a few days before the lecture to put together the (Powerpoint) lecture, (thank you Marty and Anne). The lecture was a productive exercise for me, in that it forced me to synthesize some of my findings and the ideas I’ve been developing over the course of the past nine months. It’s always a challenge to give a lecture to a group of people outside your field, and make it interesting and accessible to them. I think I managed to do so. Although my lecture was entirely in English, I was also touched that some of my Italian colleagues attended whom I’ve met during the course of my project attended, including Prof. Simona Salvo of Universita di Roma La Sapienza, and the Architetto Roberta Rosati. Roberta speaks no English. After the lecture, I asked Roberta in Italian if she understood anything from my lecture, and she replied “niente” (nothing). Despite not speaking any English, Roberta attended to show her support and encouragement for me – it was a very nice gesture, which I really appreciate.

Campanille, Vicenza Italy

Three weeks ago, I spent the entire week in northern Italy visiting sites for my project. My colleague and friend the Architetto Carlotta Coccoli was kind enough to arrange an entire week of site visits for me to projects under restoration, and insider tours of buildings of recently restored buildings, given by people instrumental to the restoration. I was really overwhelmed by Carlotta’s generosity with her own time, and in calling-in favors from her friends and professional contacts.

Carlotta Coccoli unlocking doors for me in northern Italy, (here, to a medieval church in the valley outside Brescia)

The itinerary for our week in northern Italy was as follows (we used Bescia as a home base, and did day trips from there every day):

Sunday: Train to Brescia (in Lombardy, east of Milano)

Monday: Lodi

Tuesday: Milano

Wednesday: Brescia in morning, train to Val d’Aosta (in the Italian Alps)

Thursday: Aosta

Friday: Vicenza

Saturday: Brescia, Esine valley

Sunday: train back to Rome

At the Basilica Palladiana in Vicenza, after a tour of the restoration work in progress.

I’ll write more about my trip to the north, and some of the interesting things I saw, in the weeks ahead.

The cortile at the American Academy in Rome's McKim Mead and White Building, just prior to the 2010 pinning ceremony an cortile dinner

I returned to Rome from my trip to northern Italy (two weeks ago) just in time for “Trustees Week” at the American Academy. This is essentially the busiest and most important week of the year at the Academy, as the Trustees visit from the U.S. for a series of events that include:

- readings by the Fellows in Literature,

- concerts by the Fellows in Musical Composition,

- Open Studios by the fellows in the Arts (including me),

- a series of insider tours of historic and archaeological sites in and around Rome for the Academy Trustees, led by Fellows who volunteer to lead them (including me).

- Concluding the week, the “pinning ceremonies”, where the Rome Prize winners of 2009-10 are formerly inducted as Fellows of the American Academy in Rome, followed by a very special 5 course dinner in the cortile (courtyard) of the Academy’s McKim Mead and White Building

2010 "pinning" ceremonies (induction of Fellows) at the American Academy in Rome

Returning from my trip to northern Italy just on the eve of Trustees week, I had to “charrette” (work frantically under a tight deadline) to prepare for both:

- the Trustees tour of the Pantheon, which I co-led with Prof. John Pinto of Princeton, and

- my exhibition for the “Open Studios” event at the American Academy, a public event that draws hundreds of people

Early evening with my daughter, at the Canal Grande, Venezia (Venice)

Last week, breathing a sigh of relief after the highly scheduled and busy previous weeks, I took my wife and daughter to Venice for a few days to relax and soak-in one of the world’s most beautiful and unique cities.

Red poppies bloom among the tall grass and ruins atop the Palatine Hill in Rome

Seeking shade in the Roman Coliseum

The wild poppies are now in bloom here in Rome, and the days continue to grow longer and warmer. Sunset is now around 8:15 Pm, and a week ago Sunday was the first day I actually found myself seeking shade. Of course, I was schlepping up and down the Palatine Hill (an archaeological site in Rome – where the Roman Emperors lived, just above the Imperial Forum), and the very steep steps of the Coliseum with a 17 pound bundle of joy (my 10 month old daughter) strapped to me. Nevertheless, it marked the first day I was actually hot, and willfully seeking shade.

Two weeks ago was Settimana di Cultura (Cultural Week) here in Italy – all the national museums and archaeological sites (e.g., the Forum, Coliseum, etc.) were free. In addition to it being unseasonably warm on Sunday, it also started to feel like summer in another way. The large crowds of tourists led by tour guides holding aloft an umbrella, or a brightly colored scarf tied to a broken car antenna, had reappeared in Rome after a winter hiatus, like the swallows returning to Capistrano.

View of the Coliseum from the Palatine Hill

Replacing my computer's hard drive

Last week (Week 33) marked the first week since I’ve been in Rome that I haven’t put-up a new post on my blog. My apologies – I had no functional computer last week, as a virus had rendered mine essentially inoperable. After my many failed attempts to remove the virus with several of the latest and greatest virus scanning software programs, the fantastic IT staff at my firm, Simpson Gumpertz & Heger (SGH), Fed-ex’d me a new hard drive for my computer, and then by phone, talked me through the process of replacing it myself. I had to go to a local ferramente (hardware store) and buy the skinniest screwdriver I could possibly find for the operation. I felt a bit like the airline passenger who needs to land the plane in an emergency when the pilot is incapacitated, and is talked through the landing by an outwardly calm but secretly nervous and sweaty air traffic control operator. Well, the operation was a success, and the patient (my computer) appears to be doing well. Thank you Zaki, Ben, and all.

My computer has been a lifeline for me during this year to everything back in the States – from correspondence with friends, family and colleagues to logistics like paying bills and taxes. And I only realized how remarkably dependent I had become on this technology when something went badly wrong.

The Markets of Trajan, Rome

All this reminds me of a series of ongoing discussions that architect Kiel Moe and I have been having throughout the course of this year here at the American Academy, about technology in buildings. Kiel teaches technology and design courses in the architecture school at Northeastern University, and I work for an engineering firm known for its in-depth understanding, analysis and design of building enclosures and structures, often at the leading edge of building technology. So the thrust of our discussions may come as a bit of a surprise, and even sound a bit of a counter-revolutionary… Inspired by the remarkable durability, reliability, and performance of the Roman buildings we’ve looked at, we’ve been discussing our ideas about “lower technology, higher performance” buildings ( to use Kiel’s phrase, and part of his working title for his forthcoming third book from Princeton Architectural Press).

Interior view of skylight with mechanically operated fins at the new MAXXI, Rome

Kiel and I have discussed how perhaps architecture has never truly been modern. If modernity in architecture is characterized by simplification, and using contemporary technology to achieve a rational elegance of simplicity that distills architecture to its very essence, then 20th century modernism realized only the aesthetic potential of modernity, but not its technical nor construction potential. In the late 20th century, building envelope and environmental control systems became increasingly and often unnecessarily complex, and that trend continues to escalate in the 21st century. This trend of escalating complexity is not modern, as we see it – it’s more the antithesis of modern. Technically, it’s the aesthetic equivalent of Rococo or Queen Anne Victorian – aesthetically overwhelming, but too many complex and arguably superfluous parts.

Zaha Hadid's new MAXXI (museum) in Rome

In addition to historic preservation, another aspect of my work at SGH involves investigating failures of building envelopes (e.g., walls, windows, roofing), occasionally on buildings that are only a few years old, or even brand new. This forensic work and my preservation work sound quite disparate, but they actually inform each other, as both involve critical diagnostic assessment of what is working well and proving durable, what is failing (e.g., deteriorating rapidly, or leaking), and why, and how to fix it. One thing I’ve noticed on my work on 18th and 19th century historic buildings, on 20th century modernist icons, and on contemporary new buildings is that building envelope systems have become and continue to become increasingly (and I would argue, often unnecessarily) complex, and that trend continues to escalate now in the early 21st century.

Close-up of a problematic skylight

As a profession, we continue to build walls with more and more and more layers, with each layer serving an increasingly specialized role in the buildings performance, and with increased reliance on these layers (e.g., cladding, weather-resistive barrier, air barrier, vapor retarder, thermal insulation, etc.) needing to work almost perfectly in order for the wall to perform well. It’s often unrealistic to demand or expect perfection. The old adage that “the more working parts, the more likely something is to fail” rings as true for architecture as for anything else. Relatively recent headlines and lawsuits over architectural envelope failures, ranging from simple spec. builder houses in the southeast clad with EIFS (synthetic stucco), mold and sick buildings of all types, to lawsuits of famous architects over high-profile and highly complex building envelope designs that fail and leak almost immediately after construction emphasize the pandemic nature of problems with building envelope and environmental control systems in architecture today.

A typical EIFS-clad wood framed house in the Southeastern USA

Deteriorated wood product sheathing beneath a window in an EIFS-clad house

Deteriorated wood sheathing on an EIFS-clad house that was less than 4 years old

Today, many of our neighbors seek greater simplicity and reliability in their everyday lives. Even at the forefront of popular technology, we constantly demand and receive greater simplicity and fewer working parts – our old radios, VCR’s, calendars, telephones and computers are now replaced by a single iPhone that is simpler to use, and fits in our pocket.

Another example of making an educated choice for simplicity, and even switching from high-tech to low-tech is that some of my friends and in the Boston area have switched from automobiles to bicycles for their daily commutes to work. Obviously, there are important environmental and financial considerations to their decisions, in addition to pure performance-based decisions, but financial and environmental considerations are also high on the list of most architects’ considerations in building design and construction. Among the most serious all-season bicycle commuters, many have bypassed higher-technology 10, 12 or 15 speed bikes in favor of the greater reliability, maintenance, and durability of single speed bikes. For many who have used both types of bikes (multi-speed and single speed), that extra bit of higher performance of multi-speed bikes under extreme and rarely occurring conditions (e.g., extremely steep hills) simply isn’t worth the decrease in reliability and durability, and ease of maintenance as compared to a single speed bike.

In architecture, we have largely failed as a profession to be part of this increasingly greater trend toward simplicity and durability, and this reassessment and reclaiming of elegantly simple lower tech, higher reliability ideas and designs. In contrast to the escalating complexity of contemporary design and building practices, Kiel and I have been discussing ideas for simpler, lower-technology construction practices and methods that focus on durability, reliability, and solidarity (a unified purpose of the individual members or parts) as potentially more prudent, sound and sustainable pathways forward in the twenty-first century.

Ancient Roman construction at Ostia Antica

![Louis_Kahn_Plaza[1] IIM Wikimedia Commons](https://vitruviusfootsteps.files.wordpress.com/2010/05/louis_kahn_plaza1-iim-wikimedia-commons.jpg?w=600&h=336)

A masterpiece of 20th century modernism - Louis Kahn's India Institute of Management, Ahmedabad

Stadio Olimpico, Roma

Today was a huge day for calcio (soccer) here in Rome. The top level Italian soccer league (Serie A) has two local entries – A.S. Roma, the team from here in the city of Rome, and S.S. Lazio, representing the larger region of which Rome is a part. Both teams are covered on the front page of the local sports pages. Whenever Rome plays their archrival Lazio, it’s a very big deal, and emotions run high – it’s like Red Sox versus Yankees in baseball or Michigan vs. Ohio State in college football. Today, not only were Roma and Lazio playing in a late season game, but Roma had the chance to move into first place with a victory. Cafés and bars in Rome were packed and spilling out into the street. Roma defeated Lazio 2-1 to move into first place… I was in my apartment when the game ended, but I knew the outcome from all the horns I heard beeping in the streets, and all the joyous shouting.

Entrance to the Stadio Olimpico, with mosaics and a dry, disused Fascist-era fountain in the foreground

Fascist era mosaics in the approach to the Stadio Olimpico, executed in the ancient Roman style, but with modern themes

Last Monday morning, a group of us from the American Academy took an architectural walking tour of the Foro Italico (“Italian Forum”), formerly the Foro Mussolini. The Foro Italico is a remarkable athletic complex of fascist modern architecture, mostly from the 1930’s, though expanded and modified for the 1960 Olympic Summer Games in Rome. As part of the Foro Italico tour, we were taken inside the Stadio Olimpico – the huge soccer stadium that is the home field of A.S. Roma.

Since A.S. Roma had played the day before, workers were cleaning the stands of litter from the game. After a game in the U.S., the stands of stadiums tend to be littered with beer cups, coke cups, and cardboard trays from hot dogs, nachos, etc. Not here in Rome. After the A.S. Roma game, the majority of the litter in the stands consisted of two things:

.

Debris at Stadio Olimpico after a Roma game. Photo by Robert Hammond.

- cigarette butts

- small black and red plastic canisters that contain a shot of espresso (very strong black coffee) mixed with a shot of grappa (a strong alcohol made from grape skins)

The secondary (street) facade of the Villa Medici, Rome

Also this past week, the noted French preservation Architect Didier Repellin was kind enough to give me an insiders tour of the Villa Medici (c. 1576). Napoleon Bonaparte moved the French Academy in Rome into the Villa Medici in 1803, housing the winners of the prestigious French Prix de Rome from 1803 until 1968. It stills houses the French Academy. The Villa Medici is visible from all across Rome with its perch above and just slightly to the left of the Spanish steps, although this façade facing the city is actually the rear façade. The much more elaborate front façade faces the private gardens to the northeast.

Primary (garden) facade of the Villa Medici, Rome (c. 1576)

Beneath the Villa Medici runs the ancient Roman aqueduct Aqua Virgo (it was renamed the Acqua Vergine when it was rebuilt during the Renaissance). The Acqua Vergine stills supplies the water to the famous Fountain of Trevi.

One highlight of my insider’s tour of Villa Medici was walking inside an old, abandoned settling chamber for the aqueduct that connects to the basement of the Villa Medici. The settling chamber is a huge, vaulted room, built of Roman concrete, where sand and sediment would settle out of the water, and the clean water would flow on to the rest of the city. Basically, water flowed in and filled this huge room, this settling chamber, and with the reduced velocity of water in the chamber, the sand and settlement settled to the bottom. The clean water at the top of the chamber flowed out through outlet pipes that are 5-6 feet off the floor. A simple idea, low tech idea that works well – settling chambers for the stormwater systems (e.g., drainage from streets and highways) still work the same way today, although on a smaller scale.

Although I’ve seen many examples of vaulted Roman concrete construction, I saw something in the settling chamber vault construction that I hadn’t seen before, and that relates to last week’s discussion on efficiency in Roman concrete construction. Now that I’ve thought about it, it makes perfect sense to me that I would NOT have seen it in any buildings or prominent structures, but that I would see it here, in an underground utilitarian structure that was never seen by the public, and was only seen by maintenance crews inside the aqueducts.

Roman concrete vaults in a settling chamber beneath the Villa Medici, with striated impressions left by marsh reed centering (formwork)

Since no one really cared whether these utilitarian, underground vaults were visually uniform or not, they used a technique for the “formwork” during construction that didn’t create a perfectly uniform semicircle, but that was much faster and less labor intensive than having carpenters construct wooden formwork from planks and boards. In today’s terms, it was also more green and sustainable, in that it used a readily renewable local resource, with less processing and less embodied energy (far less than in the planks or boards sawed from mature trees used for conventional formwork or centering). Didier Repellin pointed out to me that the underside of the Roman concrete vaults in part of the settling chamber have long narrow impressions in them, from reeds, and you can actually see fragments of old reeds still stuck to the underside of the vaults in some places. During construction, they bend marsh reeds across from wall to wall, in a roughly semi-circular shape, and then used the reeds as centering (formwork) for the Roman concrete vaults above. Although the old reeds are obviously quite brown and dried now, I suspect they used freshly cut green reeds, as they would be flexible enough to bend to a semi-circular shape. Since the reeds are relatively thin (roughly the diameter of a pencil), and have limited strength, I also suspect that they constructed a thin initial layer of concrete (perhaps a couple inches thick), let that concrete cure (harden) and stiffen the reed formwork, before proceeding with additional construction and weight.

Remnants of marsh reed centering in the underside of the Roman concrete vaults

In antiquity, marsh reeds grew abundantly in and around Rome, as the Tiber was not yet channelized, and flooded regularly. Thus, marsh reeds where a local, abundant, readily renewable, natural material.

The apparent construction method of these Roman concrete vaults with marsh reed centering makes me recall an excellent lecture that I heard John Ochsendorf of MIT delivered to the Boston Society of Architects Historic Resources Committee some years ago. John described how Gothic cathedrals, and Inca grass fiber suspension bridges are two very different examples of sustainability. The Gothic cathedrals, built of cut stone, are high embodied energy, but are sustainable because they provide great durability, and amortize that embodied energy over many, many centuries of service. The Inca suspension bridges, although they need to be rebuilt almost yearly, are sustainable because they are build using rope hand made from grasses that grow on the hillsides at the bridge site – thus they are built using a local, readily renewable, sustainable, natural material, that grows naturally on the site, and thus they have extremely low embodied energy and are readily renewable.

It strikes me that the construction of the Roman concrete vaults with local marsh reed centering (formwork) is not only fast and efficient in terms of construction, but that it also combines these two paradigms of sustainability in a very clever, logical manner. It uses the sustainable, renewable, low embodied energy, but non-durable material (the marsh grass) as a temporary material that can degrade shortly after use, without any adverse effect on the overall strength or durability of the structure. Furthermore, it also uses this non-durable marsh reed as a temporary material to facilitate (e.g., make more cost effective, more time efficient, less labor-intensive, and less resource-intensive) this highly durable construction (unreinforced Roman concrete vaulting) that has stood for millennia.

Reed centering in the Roman concrete vaults beneath the Villa Medici, Rome

Week 31 – The Romans’ Winter Coats Finally Come Off, and Efficiency in Ancient Roman Construction

Overlooking the center of Rome from beneath a rustic wood pergola in the Villa Sciara Parc, located on the Gianicolo.

I thought spring arrived in Rome several weeks ago, when the weather warmed and the flowers started to bloom. But clearly, I see things through the eyes of a Bostonian, not a Roman. For the past few weeks, it’s mostly been warm and sunny, with flowers in bloom, and afternoon highs in the low to mid 60’s Fahrenheit, yet Romans have largely persisted in wearing their winter scarves and coats. Last autumn, on an unseasonably hot day, my wife saw a woman faint on the #44 bus. The woman was wearing a wearing a winter parka, zipped all the way up. The bus stopped, there was a lot of commotion, and several people attended to the woman to revive her, but no one thought to even unzip her parka, let alone remove it! After recovering, the woman still didn’t unzip her parka.

From casual observation, it appears that most Romans break-out their winter coat and scarf on a certain day in the early fall, and don’t stop wearing them until a certain day in the spring, regardless of the temperatures. It must be some sort of unwritten rule, like our American convention about “no white pants or shoes before Memorial Day, or after Labor Day”.

The day before Easter in the cortile of Chiesa di San Clemente

The day before Easter, it was warm and sunny, about 65 degrees, not a cloud in the sky – I was out in a local park without a jacket, and many locals were still in their winter jackets, zipped all the way up, with a scarf. The Tuesday after Easter weekend, with the exact same weather, I suddenly saw many locals wearing light spring jackets. Thus, I suspect that the unwritten rule or local tradition in Rome might be that after Pasquetta (“Little Easter”, the day after Easter); one puts away the winter coat and breaks-out the spring jacket.

Another sign that spring has truly arrived in Rome occurred last Friday; the strawberries began to arrive at the American Academy. With the Rome Sustainable Food Project, the food served in the dining hall here is made only from fresh, local, organic, sustainable foods from local farmers. All of our food is from Italy, and 80% is from Lazio, the region of which Rome is a part. Throughout the year, we’ve been able to chart the seasons through the produce which is most abundant in our meals – peppers, pears, apples in the fall; fennel, root vegetables and Clementine in the winter; and now, with the arrival of spring, asparagus, peas and strawberries are very abundant at the meals in the dining hall.

The capitol at the ancient Roman port of Ostia Antica, on a beautiful spring day.

If you were going to build as many buildings and structures as the ancient Romans built, all across a very vast empire, well then you certainly would have needed to be extremely efficient about manner in which you built. And the Romans were. As often as I look at ancient Roman construction, I find myself continuously impressed with the efficiency of their construction.

Typical top chord connection in Roman style timber truss

Top chord to bottom chord connection in Roman style timber truss.

Stop for girts on sloped top chord of Roman style truss

In my week 21 blog, I described the simplicity, strength and efficiency of Roman connections in timber framing and trusses. The simplicity of these cuts and connections made them much simpler and faster to construct than the more complicated connections in structural timber framing we’ve traditionally used in the Anglo-American connection. With the connections they used, they were also far less inclined to weaken a member by cutting into it.

Roman style timber roof framing at San Giovanni dei Fiorentini, Rome

The Romans did not lack sophistication in their ability to make wood connections – they used complicated 3-dimensional joinery in their furniture, where the demands for a highly finished surface were greater, and the structural loadings were orders of magnitude lower. In the Romans trusses and other structural connections in heavy timber, however, it was all about speed, efficiency, and strength.

The Romans typically did not use temporary wooden formwork to construct their concrete walls. This added efficiency by saving the time and effort and materials involved in constructing the wooden formwork, and then stripping it away after the concrete cures (hardens).

Where the Romans DID use temporary wooden formwork or centering (i.e. curved formwork for an arch or vault) was where they really needed it. That tended to be on arches, their two dimensional equivalent (vaults), and their three-dimensional equivalents, domes. (N.B. – It wasn’t until Brunelleschi’s dome on the Duomo (Cathedral) in Florence that someone figures out how to build a large dome or arch without centering.) Even where the Romans used centering, they gained efficiency by:

• tending to minimize the number different sizes of arches on the same buildings , so they could reuse the centering as often as possible

• using simple wedges to release the centering after the concrete sets, so the centering can be released and removed more easily

• allowing the supports for the wood centering to remain as a permanent part of the building or structure (and often, the impost supports for the centering, which are practical to the construction process, become aesthetically articulations as well)

Brick impost/capital at the springline of the arch supported the temporary wood centering during construction (Ostia Antica)

Travertine imposts at the springline of a failed arch at Ostia Antica supported the temporary wood centering during construction of the brick arch.

Last week I mentioned that the stone or brick facing on Roman concrete walls was not only the facing, but also part of the load-bearing structure, and also the permanent formwork for the walls (in other words, it held the concrete core in place while it cured or “hardened”). This was a highly efficient form of construction, in that it omitted the need, time, and cost to build wooden formwork just to temporary support the walls during construction, (only to remove it after the concrete cures, the way we typically built concrete walls today). Furthermore, if we construct stone faced walls today, we’d typically have a mason lay the brick or stone facing on the two outer shells, with mortar, and then after that is done and cured, they fill the core with concrete.

Brick-faced Roman concrete wall at the Markets of Trajan, Rome

Architect Kiel Moe and I have been looking at many of these ancient Roman concrete walls, and from what we can tell from up-close examination, the triangular brick or wedge-shaped stone facings were NOT laid up in advance of the core – rather, they were driven-into the very stiff concrete mix, concurrent with the construction of the core of the wall. This technique of driving the facing into the core concurrently would only be possible with a very stiff concrete mix, like the Romans used – it wouldn’t be possible with the more watery concrete mixes we typically use today. Furthermore, driving the facings into a very stiff concrete mix would be far more efficient with wedge-shaped or triangular masonry facings, which the Romans clearly used. In terms of physical evidence, if the brick or stone faces were laid-up in advance, there should be a “cold joint” between the concrete core of the wall and the concrete/mortar bonding the face brick or stones, but neither of us has seen a cold joint yet after looking at broken or open sections of many of these ancient walls.

All these things lead Kiel and me to conclude that the facings were driven into the very stiff concrete mix of the core of the wall, concurrent with the construction of the concrete core. All these techniques for the stone or brick facing/formwork must have saved time, and added efficiency (not to mention durability) to the wall construction.

Today, efficiency and speed of construction is sometimes thought of as being contrary to quality and durability of construction. The manner in which the ancient Romans built, however, shows us quite clearly that these virtues need not be mutually exclusive.

From the early 20th century to today, we’ve often tended to think of efficiency as deriving from specialization. Whether it’s Henry Ford’s much acclaimed and widely influential use of the assembly line for Model T’s, or today’s incredibly specialized NFL football teams, where each position player has very particular skills and physical attributes (size or speed) suited to a particular task, we often tend to focus on a model of efficiency whereby specialization of the many individual parts is key to the efficiency of the (relatively complex) whole.

That, however, is only one model of efficiency… The ancient Roman examples of the multiple roles played by single elements – e.g., brick or stone wall facings (weathering facings, load-bearing structure, and permanent formwork) and the imposts of arches (supporting temporary centering, supporting permanent arches, and aesthetic articulation) demonstrates another model of efficiency – one of versatility, where fewer single elements each playing multiple roles that contribute to the efficiency of the (relatively simple) whole.

Brick-faced concrete structure at Ostia Antica

Week 30 – The Design of Concrete for Durability by the Ancient Romans, Part 2 – Protecting Concrete from the Weather

View across the center of Rome from atop the Gianicolo, with the Apennine mountain range in the background

This past weekend was a major holiday weekend here in Rome. Sunday was of course Easter Sunday (Pasqua di Resurrezione), and the following day, Monday, is also a national holiday – Lunedi dell’Angelo, or “Pasquetta” (Monday of the Angel, or “Little Easter”). Other than restaurants and bars, just about everything in Rome was closed yesterday for Pasquetta, including the American Academy.

My daughter, wearing her partisan colors for the Red Sox - Yankees baseball game.

Yesterday morning on Pasquetta, I also celebrated an unofficial but significant Boston holiday with about 10 friends – opening day of the baseball seasons – by watching the Red Sox – Yankees opening day game. We watched the game with some classic American ballpark junk food – roasted peanuts in the shell (impossible to find here in Rome) and Cracker Jack (yes, they still exist), Coca Cola, beer, sausages, and ice cream sandwiches. The peanuts in the shell and Cracker Jack are impossible to find here in Rome, but I had some friends who recently visited from the States bring them for us.

Later in the afternoon, we had a cook-out in Bass Garden. Getting the fire lit with damp wood was a challenge, but with considerable help from 11 year old Turiya Adkins, we got it done. Thank goodness she went to Pioneer camp.

The wood fire finally going at our cook-out on Pasquetta

The weather this weekend must have been enough to drive the locals crazy. It was beautiful, warm sunny and blue skies for the work week just before the holiday; rainy, chilly and gray for the two day holidays on Sunday and Monday, and beautiful sunny and warm again this morning, Tuesday morning, as everyone headed back to work.

Tuesday morning - a beautiful sunny day in the Bass Garden, after a soggy, rainy weekend

As a bit of background, during the last two weeks ago, I made the points that:

- Concrete construction from ancient Rome has proved far more durable, relative to its age, than the concrete on most 20th century modernist structures that I’ve worked on. As a result, we have something to learn from the ancient Romans about designing concrete for durability

- Differences in the actual materials themselves (ancient Roman concrete versus modern concrete) don’t nearly begin to explain the vast difference in durability of the two

- Rather, the great difference in concrete durability then versus now derives from how the ancient Romans designed buildings and structures with this material, versus how we’ve designed with it in the 20th century.

- The principles I see in the ancient Romans design of concrete, which helped give it remarkable long-term durability, are quite simple. They are:

- If you can possibly avoid doing so, DON’T REDUCE CONCRETE’S DURABILITY BY REINFORCING IT.

- PROTECT CONCRETE FROM THE WEATHER, particularly from water

Brick and stone faced concrete walls at Ostia Antica, the ancient Roman port near Rome.

Although these two principles are very simple, they eliminate or greatly mitigate essentially all deterioration mechanisms of concrete. In other words, if the concrete has no internal ferrous (e.g., steel, iron) reinforcing, and if it never gets wet, essentially none of the deterioration mechanisms of concrete [e.g., alkali-silica reaction, erosion or leaching of the binder through water ingress, freeze/thaw action, crystallization of soluble salts (subflorescence), corrosion of the reinforcing steel, which can occur as a result of carbonation, and which can be accelerated by the presence of salts and or differences of electric potential] apply.

Last week, I discussed the first principle that we should learn from the Romans’ durable constructions with concrete – don’t reduce concrete’s durability by reinforcing it.

This week, I’ll discuss the second principle (as I see it) that we should learn from the Romans design for durability with concrete – protect concrete from the weather.

Sert's Peabody Terrace housing complex at Harvard Univ.

In mid-century modernist buildings I’ve worked on (buildings by Paul Rudolph, Josep Lluis Sert, Eero Saarinen, etc.) the concrete is exposed on the exterior. Thus, they are subject to a more severe exposure to the elements and weathering, and in particular, water, than the ancient Roman buildings were.

In Roman concrete buildings, the concrete is not exposed on the exterior. Typically, Roman concrete walls were faced with either brick or stone.

1st c. A.D. brick and stone faced concrete walls at Ercolano. Note the remnants of stucco covering at the bottom of photo.

In fact, this stone or brick facing was more than a veneer or cladding, it was essentially a combination of facing and permanent formwork. In other words, today we typically build concrete walls by building wood forms to hold the “wet” concrete mix until it cures, and then we strip the forms, and reuse them. The Romans used the brick or stone as the formwork, to hold the concrete in place until it cured, and then left it in place as the permanent facing, thus protecting the concrete from the most severe exposure to the weather.

.

Stone facing/permanent formwork on Roman concrete walls at the columbarium at Villa Doria Pamphilj

Thus, the stone or brick facing on a Roman concrete wall was an interesting hybrid by today’s construction language and techniques. It was:

- structurally integral and composite with the concrete core of the wall, thus, it was structural and load bearing

- permanent formwork for the construction of the wall

- a facing for improved durability (in my opinion) of the concrete core

.

.

.

.

2-1/2 inch thick stucco on brick-faced concrete wall (1st c. A.D.) at Ercolano

In most cases on ancient Roman construction, not even the brick and/or stone facing on the concrete were left exposed – they were covered by a layer of “sacrificial” stucco facing that was usually 2-3 inches thick. This sacrificial stucco facing really took the brunt of the weather. As a result, it deteriorated regularly, and had to be renewed. The stucco, however, saved the concrete walls from weathering, and thus contributed greatly to the long term durability of the stone or brick-faced concrete walls.

Curia Iulia (29 B.C.), in the Imperial Forum in Rome

Because of its sacrificial nature, very little of this stucco survives in the city of Rome today, although a fragment survives on the Curia Iulia (built 44-29 B.C.) in the Roman Forum, up high on the brick wall, sheltered by a cornice. The fact that any exterior stucco survives 2,000 years is truly remarkable. The fact that the stucco which survives is located directly beneath a sheltering cornice is no accident – it is indicative of the ability of cornices, ledges, and other projections from the façade to protect the façade from the weather (for more on this, see my Week 11 Post).

Surviving ancient Roman exterior stucco on the Curia Iulia (29 B.C.), scored to look like stone blocks.

In Ercolano (Herculaneum), which was buried by the eruption of Vesuvius in 79 A.D. and thus sheltered from direct exposure to the weather until excavated in the 20th century) much more of this sacrificial exterior stucco survives.

Surviving 1st century A.D. exterior stucco rendering on stone-faced concrete walls at Ercolano

In my work in the U.S., I’ve encountered a couple examples of 20th century concrete buildings that utilized stone facing, or stucco facing. On these buildings the concrete is in far better condition than other concrete buildings of roughly the same age, in a similar climate.

Detail of stone-faced concrete wall at Morse & Stiles Colleges, Yale

Morse and Stiles Colleges at Yale, a significant modernist complex from 1961 designed by Eero Saarinen, is constructed with stone (mostly granite) faced concrete. Because the concrete wall is reinforced, the stone facing also provides more cover (depth, and protection from the weather) for the embedded reinforcing steel. Instead of the typical 1-1/2” depth of the reinforcing steel on exterior concrete walls built in the 1960’s, Morse and Stiles typically has 5-6 inches of cover on the steel. Consequently, the concrete walls at Morse and Stiles are in much better condition than the other exterior concrete walls I’ve examined on other 1960’s architectural icons of modernism.

At Shangri La, Doris Duke’s fabulous 1937 mansion complex in Honolulu Hawaii, the buildings are right on the sea wall, and have a very severe exposure to the weather. Standing at the buildings, you can actually feel the salt spray on your face when the large waves roll in at high tide each day. This daily exposure to salt spray, and the heavy rainfall on the island make for a severe exposure to the elements for a reinforced concrete building. Although the concrete walls have no brick or stone facing, they have always had an exterior stucco rendering (parge coat) on the surface, which has always been painted. Despite the very severe exposure to the elements for over 70 years, the concrete on Shangri La appears in good condition, far better than most of the concrete of a similar age in a similar rainy, marine climate, and also far better than most of the exposed (no stucco coating) concrete I’ve inspected on much later 1960’s buildings.

Shangri La, Honolulu HI - view from the playhouse looking toward the main house

While neither of these complexes (Shangri La, and Morse & Stiles Colleges) was inspired by Roman concrete construction, and while neither looks the least bit Roman, both happened to utilize a technique (stucco coating, and stone facing respectively) that the Romans utilized on their concrete walls. It’s no coincidence that both of these 20th century complexes are generally proving more durable than most similar aged concrete buildings in similar climates.

Interior view of the unreinforced concrete dome of the Pantheon (protected from the weather by metal roofing for essentially its entire existence).

Perhaps the best example of all from ancient Roman construction of providing for the durability of concrete by protecting it from the weather (e.g., water) is the roof of the Pantheon (126 A.D.). The roof was originally covered with bronze roof tile, but the bronze was removed by the Emperor Constans II in 663 A.D. Constans II at least had the good sense to have another roof put on the Pantheon, this one lead. Thus, the unreinforced concrete dome has continuously had some form of metal roofing protecting the concrete from the rain for essentially its entire history – over 1,800 years.

Week 29 – The Design of Concrete for Durability by the Ancient Romans, Part 1 – Reinforcement (or lack thereof)

A beautiful spring afternoon in Rome's Villa Doria Pamphilj Parc

This past week, the spring weather here was absolutely beautiful – we’ve enjoyed gorgeous blue skies, and afternoon highs of about 64 deg. F. The days have grown noticeably longer. We turned our clocks ahead this past weekend for daylight savings, so sunset is now around 7:30 PM. It’s now holy week in Rome – yesterday was Palm Sunday (Domenica delle Palme), and this coming weekend will bring Good Friday and Easter Sunday (Pasqua di Resurrezione). In many food and pastry shops in Rome, the display in the storefront windows for Easter rivals that for Christmas. Below are some photos from Innocenzi, one of my favorite shops in the Trastevere neighborhood in Rome, their storefronts full of Easter goodies.

A window at the "Innocenzi" shop in Rome's Trastevere neighborhood

Another storefront window at Innocenzi

Last week I made the case that:

• Concrete construction from ancient Rome has proved far more durable, relative to its age, than the concrete on most 20th century modernist structures that I’ve worked on. As a result, we have something to learn from the ancient Romans about designing concrete for durability

• Differences in the actual materials themselves (ancient Roman concrete versus modern concrete) don’t nearly begin to explain the vast difference in durability of the two

• Rather, the great difference in concrete durability then versus now derives from how the ancient Romans designed buildings and structures with this material, versus how we’ve designed with it in the 20th century.

Having discussed the first two points last week, I’ll pick up on the third point this week.

Baths of Caracalla, Rome

Concrete has many, many mechanisms by which it can deteriorate – first and foremost, corrosion of the reinforcing steel, which can occur as a result of carbonation, and which can be accelerated by the presence of salts and or differences of electric potential. Even if it were plain (e.g., unreinforced) concrete, it can still deteriorate by alkali-silica reaction, erosion or leaching of the binder through water ingress, freeze/thaw action, crystallation of soluble salts (subflorescence) within the concrete that disaggregates the binder, etc.

The principles I see in the ancient Romans design of concrete, which helped give it remarkable long-term durability, are quite simple. They are:

1. If you can possibly avoid doing so, DON’T REDUCE CONCRETE’S DURABILITY BY REINFORCING IT.

2. PROTECT CONCRETE FROM THE WEATHER, particularly from water

Although these two points are very simple, they eliminate or greatly mitigate essentially all deterioration mechanisms of concrete. In other words, if the concrete has no internal ferrous (e.g., steel, iron) reinforcing, and if it never gets wet, essentially all of the deterioration mechanisms that you see listed above don’t apply. Some discussion of the first principle follows below.

Brick-faced Roman concrete at the Markets of Trajan (2nd c. A.D.)

Concrete is basically a man-made stone. Like natural stones, concrete is very strong in compression (i.e., pushing together, crushing), but very weak in tension (i.e., being pulled apart) Adding steel reinforcement to concrete adds great tensile strength, and allows us to use it the way we have in the 20th century – for beams and frames – that otherwise wouldn’t be possible. However, that increase in tensile strength comes at a price -by reinforcing concrete with steel, we also greatly reduce its long-term durability. This, the typical manner in which we have reinforced concrete with steel “rebars” in the 20th century has added a major Achilles heel to the durability of the concrete – corrosion of the reinforcing steel is one of the most common and pervasive factors that severely limits the durability of twentieth century concrete structures.

Roman concrete vaults at the Baths of Caracalla, Rome

This first principle (don’t reduce concrete’s durability by reinforcing it) is probably as much about the broader philosophy of materials and structures, as much as it is about the mundane aspects of construction.

• In the twentieth century, what we’ve done is take a material (concrete) that is very weak in tension, and we combine it with another material (embedded reinforcing steel) to make it something that it is not (strong in tension), so we can use it in ways and in forms to which it is not naturally suited (e.g., beams), and that demand tensile and flexural strength, which of course plain concrete does not naturally have. It’s a very clever, but also a highly manipulative approach to engineering and materials. In the typical way in which we’ve reinforced concrete in the twentieth century, we arguably traded one type of strength (tensile) for long-term durability, particularly on exposed concrete.

• By way of contrast, what the Roman’s did was accept the inherent limitations of low tensile strength of the concrete material, and designed their structural forms to suit this material. Thus they designed structural forms in plain (unreinforced) concrete (walls, arches, vaults, and domes) that required a great deal of compressive strength (which concrete has), but require almost no tensile strength. Their approach did not require any trade-off or potential reduction in the inherent durability of the material.

Exterior view of the drum of the Pantheon (brick-faced Roman concrete, 2nd c. A.D.)

These are two entirely different approaches and concepts of engineering and materials. Our 20th century approach to concrete design highly manipulates the material to make it work for the structures and forms that we want, while the ancient approach to concrete design accepts the material and its strengths and weaknesses, and then designs structures and forms that are suited to those strengths and weaknesses. Neither one is right or wrong, they are simply very different approaches.

I wouldn’t even go so far as to say that these two approaches to structural design in concrete are typical of “ancient” versus “modern” approaches in general – in fact, the Romans manipulated many materials to better suit their needs of design and construction – even plain unreinforced Roman concrete is of course a man-made engineered material made from a very careful process involving multiple natural materials (limestone, pozzolana, water, sand, rocks).

As a side note, it would be easy to say, “well, of course the Romans didn’t reinforce concrete – they didn’t have that technology”. While it’s true that the Romans didn’t use reinforced concrete with tensile reinforcement in the same way that we have used it throughout the 20th century, they actually did have and did use a form of linear ferrous tensile reinforcing in some of their stone-faced and brick-faced concrete structures. In some buildings, particularly in the baths, the ancient Romans used iron tie bars as tensile reinforcing elements to restrain the thrust on the innermost or outermost arches or vaults – that is, arches or vaults that didn’t have an adjacent arch or vault to counter-act that thrust. Chapter 6 of Lynne Lancaster’s excellent book, Concrete Vaulted Construction in Imperial Rome shows and explains this very clearly, with some very nice drawings and diagrams, and also summaries of previous scholars work on this topic. But it’s interesting to note that the Romans did NOT use tensile (“tie”) rods everywhere – they only used them where they essentially had no other option – in essence, where they had no neighboring arch or vault or wall to resist the thrust. Elsewhere, they just used plain (unreinforced) concrete, but they designed and used the material to its inherent strength – compression.

Concrete vaults and brick-faced concrete walls at the Markets of Trajan in Rome (c. 110 A.D.)

Today, it’s really not practical to think that we could build large apartment buildings and office towers entirely out of unreinforced concrete, with vaults and arches and domes, as the Romans did. And I’m not suggesting that. But we should nevertheless derive a couple simple lessons from the ancient Romans about designing concrete for durability.

The first lesson comes back to that first principle I see in the Romans designs in concrete (don’t reduce concrete’s durability by reinforcing it). Today, we will most often need to use reinforcing with concrete, but we need to think creatively about reinforcing it in ways that does NOT reduce the durability of the concrete, (as, unfortunately, we’ve so frequently done in the twentieth century). We need even more durable alternatives to the galvanized or epoxy-coated reinforcing bars we’ve had for years. We’ve been rebuilding concrete bridge decks every 15-20 years with epoxy-coated rebars, and we are right back there again 15-20 years later, rebuilding them again. I’m encouraged to see multiple advertisements in Civil Engineering magazine for stainless steel reinforcing bars for use in concrete.

Interior concrete column deterioration at locations of internal steel reinforcing ties on an architecturally significant 1960's building designed by Paul Rudolph

And, back to historic preservation, a colleague of mine in Boston, Wendell Kalsow of McGinley Kalsow Assoc. Architects, recently used stainless steel reinforcement in the new replacement pieces for deteriorated early twentieth century “cast stone” (architectural concrete) in the exterior restoration of Gasson Hall, a landmark building at Boston College. This makes perfect sense to me – if we are spending all that money on scaffolding and mobilization and labor and construction costs to replace a lot of badly deteriorated cast stone that is less than 100 years old, for a small increase in the cost of the replacement material, and no increase in the labor cost, we can provide far greater durability, and not be doing the same project all over again in another 80 years.

Other non-ferrous (and non-corrosive) types of reinforcing(e.g., carbon fiber, glass fibers, basalt fibers) also hold promise for more durable reinforced concrete, and much research is being done on those fronts. But we’ll need to get past other potential problems, like alkali attack of glass fibers, before those methods for reinforcing concrete are truly ready for “prime time”.

Designers and contractors should realize we will all occasionally encounter instances where we actually do NOT need to reinforce concrete – we should learn to recognize those instances, and realize we can often gain durability, and reduce cost, as a result. Engineers and architects should remember that the code (ACI) does allow plain (unreinforced) concrete, in instances where it makes sense – in fact, there’s an entire chapter in the ACI Code on plain concrete. I can think of a couple examples on my projects where we used or recommended unreinforced concrete.

One example was a peer review I was doing for an architecture firm on the design of a very high-end house in Silicon Valley California. The design had an indoor swimming pool, with precast architectural concrete blocks along the pool edge, partly in the chlorinated water, and partly out. We recommended omitting the reinforcing steel in the blocks – because they didn’t need to be reinforced, and because the reinforcing would reduce the durability of the blocks in that severe environment.

"Threading the needle" - reinstalling a 100 ft. historic flagpole in its new plain concrete foundation at Yale

Another example was on a plaza rehabilitation project at Yale University, at the Beinecke Library/Hewitt Quadrangle, we used plain (unreinforced) concrete for a couple different things. One was the new foundation of an historic flagpole that we were resetting. The other was the foundation for a new, very large granite bench, designed by The Olin Studio of Philadelphia. In both cases, reinforcement wasn’t structurally necessary, and only would have served to limit the durability of the concrete over the long-term, in the wet below-grade environment. Thus, in both cases we used unreinforced concrete.

Yale's Beinecke Plaza/Hewitt Quad, with the Olin-designed monumental granite benches in the foreground left and right, and the reset historic flagpole at center

Next week, I’ll conclude this thread on concrete with some discussion of how the ancient Romans designed for durability by protecting concrete from the weather.

Spring BBQ at the American Academy in Rome. Photos and collage by Annie Schlecter.

Yesterday, Sunday, was celebrated here at the Academy as the first full day of spring with a day-long cookout in the Bass Garden. It involved sausages and pot-luck offerings, games of bocci and kickball, tree-climbing and bike-riding by the kids, and lots of cookie eating by young and old alike (as captured in the photos above by Annie Schlecter). Unfortunately, I spent the day indoors, coping with severe hayfever from some nasty spring allergies. According to an informational pamphlet in my doctor’s office, Rome is the “allergy capital of the world”. In the autumn and winter, that claim struck me as odd, but now with the early bloom of spring, and pollen, I have no reason to doubt it.

The Baths of Caracalla, Rome (3rd c. A.D.)

In recent years, probably half my historic preservation work back in the States has been on 20th century modernist concrete buildings. These aren’t exactly what the average person on the street might picture if you said “think of an historic building” – although they may be very significant in the history of modern architecture. Personally, I’m fascinated with and love working on these buildings and the challenges they pose. I’ve undertaken projects on exposed concrete buildings from the 1960’s designed by Eero Saarinen, Josep Luis Sert, Hilario Candela, Paul Rudolph, and others. Although these buildings are not yet 50 years old, many already exhibit extensive deterioration of the exposed concrete. Despite their young age, ongoing maintenance and repair of these buildings can be a major and costly undertaking.

Paul Rudolph's UMass Dartmouth campus (originally Southeastern Mass. Technological Institute), c. 1963

All of my experience with these modernist concrete structures makes me even more appreciative of the durability of the Roman concrete structures all around me here in Rome and central Italy. Even with sites like the Baths of Caracalla (3rd. century A.D.), which are now massive ruins, I’m amazed just how much of the concrete has actually survived – not only the ravages of time, but sacking by the Goths, being used as a quarry for materials for other construction from the middle ages through the Renaissance, etc.

Markets of Trajan (c. 110 A.D.), Rome, with concrete vault in main hall

With Roman concrete structures that are more intact, like the Baths of Diocletian (early 4th century A.D.), and the Markets of Trajan (early 2nd century A.D.), I’m even more amazed at how much Roman concrete has survived the ravages of time (and war, and quarrying for materials).

Clearly, the Pantheon (early 2nd century A.D.) has them all beat when it comes to durability and intactness of a Roman concrete structure (see my Week 6 post for an appreciation of the Pantheon).

Typical concrete spall on a significant modernist building from the mid 1960's near Boston

By and large, it seems that many Roman concrete structures have proven more durable than many iconic mid-twentieth century concrete structures (relative to their respective ages). The obvious question, then, is “What can we learn from Roman concrete construction that would help make contemporary concrete construction more durable?”

One thing we can learn from the Romans about concrete mix design is merely a reminder of something we already know. All engineers know that adding a lot of water to concrete when mixing it (having “a high water/cement ratio”) makes the concrete weaker, more absorptive, more prone to shrinkage cracking, and generally less durable. However, on a construction site it’s often an ongoing battle between the engineer who wants a low water/cement ratio for the reasons stated above (which makes the uncured concrete thicker and less fluid, and more difficult for the contractor to mix and pour), and the contractor who wants to add more water (making the concrete soupier and more fluid, and thus easier to mix and pour – but also making it weaker, more prone to shrinkage cracking, and less durable). From the references I’ve reviewed, Roman concrete was extremely stiff – they used very little water by today’s standards, making the their concrete a “zero slump” concrete mix (in today’s terminology). To put it more simply, in layperson’s terms – most modern concrete adds enough water to make it the consistency of applesauce – Roman concrete added far less water – it was more like the consistency of peanut butter.

My preservation colleagues who are lime aficionados will be quick to point out one difference between ancient Roman concrete and modern concrete – the binder (e.g., the “glue” that sticks the concrete together). Roman concrete is made with a binder of lime and pozzolana, whereas modern concrete is made with a binder of Portland cement. To many of us working in historic preservation, hearing the words “lime” and “Portland cement” in the same sentence sends up a huge red flag – we’re tempted to immediately launch into an emotional, scathing diatribe about the evils of Portland cement, and the virtues of lime. But to be perfectly frank, when we really delve into it, the binder for modern concrete (Portland cement) and the binder for Roman concrete (lime plus lots of pozzolana) are actually much more similar than they are different. (I probably risk being ostracized by my lime-aficionado preservation colleagues for writing this apparent heresy). But here’s why I say they are actually more similar than they are different different: in the end, a Roman concrete binder (consisting of lime + pozzolana), and a Portland cement binder both involve a mix of these two things:

- 1) calcareous materials from fired, crushed limestone (e.g., calcium hydroxide) with

- 2) a combination of fired silica (e.g., silicon dioxide) and alumina (e.g., aluminum oxide) that are reactive when mixed with water.

In both cases (Roman and Modern concrete binders), the latter constituents (the silicas and aluminas) increase the strength, decrease the “cure” time, and create the characteristic that it will cure underwater. In both cases, the calcareous and the silca/alumina constituents combine to form calcium silicate hydrate, a tenacious binder that gives both great strength. Both the ancient Romans the moderns create the calcareous constituent using basically the same process – by firing limestone in a kiln and grinding it.

With all the similarities listed above, the only fundamental difference between the Roman and modern concrete binders is how they obtain the fired, reactive silica and alumina constituent. With the ancient Romans, the geological activity of the volcanoes in the Bay of Naples has already naturally created the fired and ground silica and alumina (as “pozzolana”, volcanic ash, occurring in the soil all over the region), so the Romans could simply dig it up out of the ground, just beneath the shallow topsoil. However, in other areas of the world without so much volcanic activity, we aren’t quite so fortunate to have pozzolana lying around in abundance on the ground. Thus in the case of Portland cement, natural materials (e.g. clay) containing these silica and alumina constituents are fired in a kiln and ground to create them.

The volcano Mt. Vesuvius, in the Bay of Naples

Other differences between Roman concrete and modern concrete as a material, such as the typical size of the aggregate (rocks or sand), or methods of compaction (by hand,or mechanically) are to me, insignificant in explaining the major difference in durability between the two.

Concrete at the Markets of Trajan, with typically large (fist-sized) stone aggregate

In a way, perhaps that’s all a little disappointing – wouldn’t it be much more glamorous (and probably make for an exciting documentary on The History Channel or The Discovery Channel) if there were some “secret ingredient” in Roman concrete that we could rediscover with some new high-tech. analysis, and use it to make our contemporary concrete structures more durable?

The Pantheon, Rome (c. 126 A.D.)

That, however, simply isn’t the case. Roman concrete is NOT technically superior to modern concrete as an isolated material– in fact, I would argue that air entrainment and other advances make today’s best concrete mixes superior in strength, density and durability to Roman concrete as an isolated material. In building construction, however, we seldom if ever use materials in isolation – we use them as parts of assemblies, and systems (e.g., walls, foundations, vaults, domes), and most importantly, as part of a larger design where we detail and integrate various materials and systems. As is often the case, the key to durability here relates less to “secret ingredients” or advanced chemistry or the theoretical properties of materials in isolation, and it relates more to how we design and detail the different parts of the building as an integrated whole, for durability, using materials to their strengths, minimizing their weaknesses, and minimizing their exposure to agents of deterioration. In short, the greater durability of Roman concrete compared with modern concrete isn’t so much about the properties of the concrete itself, it’s much more about how the Romans, and how we modern designers, design with it.

More on this next week, with some specific design examples of how the Romans designed for durability with concrete.

Exterior view of brick-faced concrete at the Markets of Trajan, Rome (c. 110 A.D.)

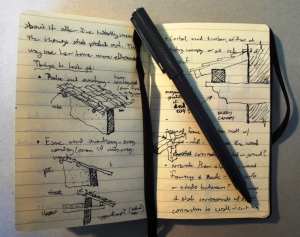

One of my small notebooks.

Some time ago, Architect Robert Bateman posted a question to my blog asking about my methodology of studying buildings in the field, and whether I prefer hand sketches, measured drawings, or photographs. I posted a short answer, but I promised to write more on this topic at a later date – so, here we go…

My drawing table in my studio at the American Academy.

In my work at Simpson Gumpertz & Heger (SGH), I usually have the benefit of being able to direct a contractor to take cores or make exploratory openings in the building for me, to enable me to examine and sample normally concealed materials and details of construction (e.g., within the walls). Here in Rome that isn’t the case – I’m not about to ask (and I certainly would not get) permission to make holes in 1,000 year old buildings! Additionally, I don’t have access to the vast array of the fancy equipment, like boroscopes and ground penetrating radar, that I have available to me at SGH.

My typical investigative tools here in Rome.

Thus, in my research here in Rome, I’m more reliant on purely visual observation than in my work back in the States. But in a way, it’s a good exercise for me in observation. One of my colleagues at SGH has often said, and I agree, that despite all the fancy gizmos we have, your eyes are still the best investigative tool you have. My small kit of tools that I take with me to sites here in Rome is limited to things to help me see, and to measure what I see – things like a tape measure, flashlight, mirror, magnifying glass, etc. Here, I simply don’t carry the tools for making openings or taking samples (e.g. knife, chisel, hammer) that I would keep in my tool bag back in the States.

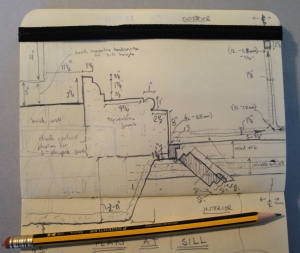

Photo of the sill and sub-sill drainage system on the windows at Palazzo Braschi (see Week 20 post). Useful, but it doesn't tell the whole story...

Photographs are great, and I take many, but I find that drawing is really essential to the examination and investigation of buildings, not only here in Rome where my examination of buildings is purely visual, but even back in the States where I have many other tools at my disposal. One fundamental methodological difference between a taking a photograph versus making a sketch in the field is this: taking a photo doesn’t force you to ask and answer questions – one click and you’re gone. Making a sketch forces you to keep asking and answering questions as you draw – (e.g., How does this connect to that? How deeply embedded is this? What size is that?) These questions are essential to construction details, and how they perform. In asking these questions in the field, I have a chance to realize critical information that I am missing, and I can seek to find the answer while on site – perhaps looking at a different angle, with a flashlight, or peeking in a small existing opening at an area of deterioration will reveal the answer.

Dimensioned sketch of a window sill/jamb plan at Palazzo Braschi

Dimensioned sketch of a window sill section at Palazzo Braschi

.

.

.

.

.

.

.

.

.

.

.

.

Some architects and many students like to carry a large sketchbook – 8-1/2 x 11 inches or so – but I find that for me, portability is key, and thus smaller is better for me. I choose sketchbooks that are small enough to fit in my back pocket, so I can still have it with me at a museum or archaeological site where bags are not permitted, and so I can have my hands free whenever needed on the construction site (e.g., to climb a ladder).

Keeping the sketchbook small means it’s also easy to have it with me at all times. Thus if I am waiting for a bus or train, or riding one, I can be working-out, synthesizing, or summarizing ideas or findings, as below:

Some ideas I summarized in my sketchbook while on a train.

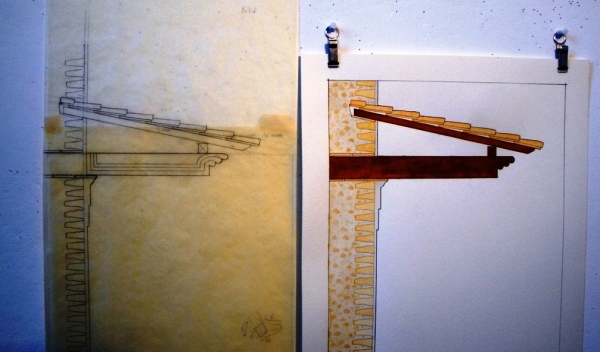

Being back in my studio allows me to create measured drawings from my hand sketches and measurements from the field. This allows me to create a nicer, cleaner drawing to present my findings, but it also creates a “check” of how things fit together when actually drawn to scale.

I usually start the measured drawings on inexpensive trace paper, to work all this out with some erasing and reworking, and then, once I have it worked out, I make a final drawing on some nice watercolor paper. These watercolor drawings will give me something to show at the open studios here at the American Academy on May 27 (please come if you are in Rome). But the watercolors aren’t only to make the presentation drawing pretty, but also to help convey a sense of the various materials of the construction to the viewer. For example, in the the images below, in the watercolors at right, it should be more obvious than in the trace paper drawings at left which materials are wood, terra cotta, stucco, etc.

Section of a roof eave in Trastevere, Rome

Sections of the entry roof at the Casa Del Salone Nero (house of the black living room) at Ercolano Scavi (the Herculaneum excavations)

The painter Stephen Westfall at his exhibition opening.

Throughout the year here at the Academy, we are treated to an almost constant series of events by our colleagues – gallery exhibitions by the fellows in visual artists, readings by the literature fellows, concerts by the fellows in musical composition, lectures by the historians, etc. Friday was the latest such event, the opening of a gallery exhibition by the painter Stephen Westfall. Stephen’s exhibition, which I really appreciate, includes both work on canvases, as well as large scale paintings directly on the gallery walls that he did with the help of some dedicated volunteers.

Opening of Stephen Westfall's exhibition at the American Academy in Rome, 12 March 2010.

Stephen’s exhibition followed an exhibition in that same gallery space by the Dutch Artist and Affiliated Fellow Roma Pas.

The visual artist Roma Pas

Sadly, this past Monday morning marked Roma’s departure from the America Academy to return to the Netherlands. By way of background, those at the Academy in different capacities have different lengths of stay. The Academy’s permanent Staff tend to remain in employment here for years on end. Fellows like myself are here on an 11 month term, a full academic year. Affiliated Fellows like Roma, as well as Residents, are usually here for a few months. Visiting Artists and Visiting Scholars are usually here for only a couple weeks. Thus, aside from the Staff and Fellows, the faces in the dining room at the Academy are constantly changing throughout the course of the academic year, as new artists and scholars arrive, and others depart.

One of the great joys of being here for the entire year is the friendships that we have a chance to form with those who are here for very long stays. On the other hand, it is with sadness that we mark the departure of someone who has been with us a long time, and who feels like part of our extended family, like Roma.

At a happy hour event last Sunday evening, at which we toasted Roma’s departure, several people arrived wearing those cheap tourist T-shirts (sold at the “gack” souvenir stands all over the center of Rome), that read “I Love Roma” – a funny and heartfelt salute to our departing friend Roma Pas.

One of Rome's omnipresent souvenir t-shirt stands - this one is in Campo de Fiori

Week 26 – Architectural Darwinism, Modernism, and Celebrating the Third Anniversary of the Rome Sustainable Food Project

In last week’s blog, I discussed Foreman Comon’s attention to detail on the clay roofing tile overhang dimensions at eaves. Architect Chris Decareau posted an interesting comment that related in part to a perception that contractors who work on restorations (like Comon) show greater attention to detail, and a greater inclination to suggest the “best” way to do something, as compared with contractors who work on new, modern construction.

Foreman Comon (in blue) and his crew install clay tile roofing atop the cortile of Palazetto Cenci.

My pencil and watercolor drawing of a highly-evolved roof eave detail on a building in the Trastevere section of rome